Successful project completion:

CHP-Plant

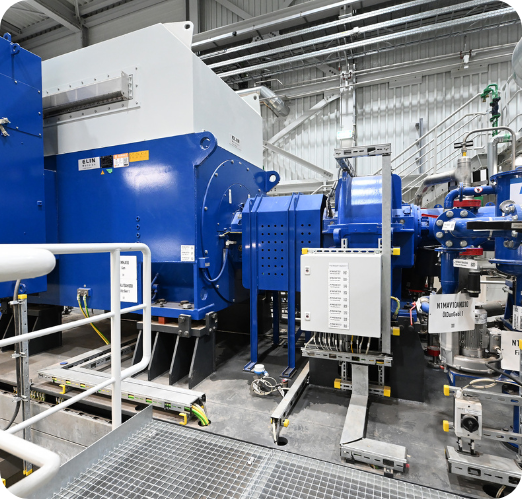

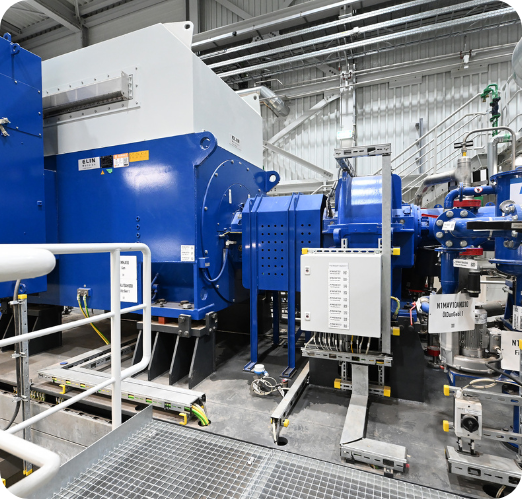

SAR supplies central process control technology for Europe’s first fully automated large-scale CHP plant

A significant milestone for industrial energy supply in Europe: E.ON and MM Neuss (Mayr-Melnhof Karton Group) have jointly commissioned the first fully automated combined heat and power (CHP) plant of this size.

The new plant will supply the cartonboard production in Neuss with electricity and heat in a highly efficient, flexible and climate-friendly manner – and sets new standards in terms of automation, digitalization and sustainability.

SAR

SUCCESS

“We are proud to be part of a project that not only sets technical standards, but also makes an important contribution to industrial decarbonization.

The collaboration with E.ON and MM Neuss was characterized by a spirit of innovation, a high level of professionalism and a clear focus on the future:2

SAR as a technology partner for future-proof automation

As a long-standing partner for sophisticated automation solutions, SAR Prozess- und Umwelttechnik played a key role in the technical implementation of this flagship project. Our service package included:

- The complete higher-level process control technology based on Siemens PCS 7

- The implementation of all automation functions for fully automatic operation

- The installation of the entire measurement technology including billing and emission measurements

- The integration of a video system for operational monitoring

- Cabling and electrical installation for our scope of delivery

Technology for the energy transition

The control architecture implemented by SAR is an integral part of the innovative E.ON IQ Energy® solution, which enables fully digitized operation for up to 72 hours unattended. SAR thus makes a significant contribution to the high efficiency, safety and flexibility of plant operation.

The CHP plant in Neuss achieves outstanding values with a fuel efficiency of up to 91% and CO₂ savings of around 22,000 tons per year. It is already prepared for the use of hydrogen – a forward-looking concept that SAR supports with modern automation and measurement technology.