SAR developed a complete MES-system for BMW Landshut and BMW Dingolfing at the dashboard and leather skin production facilities.

The system represents the vertical connection between the production level and the ERP system.

Legal requirements for airbags

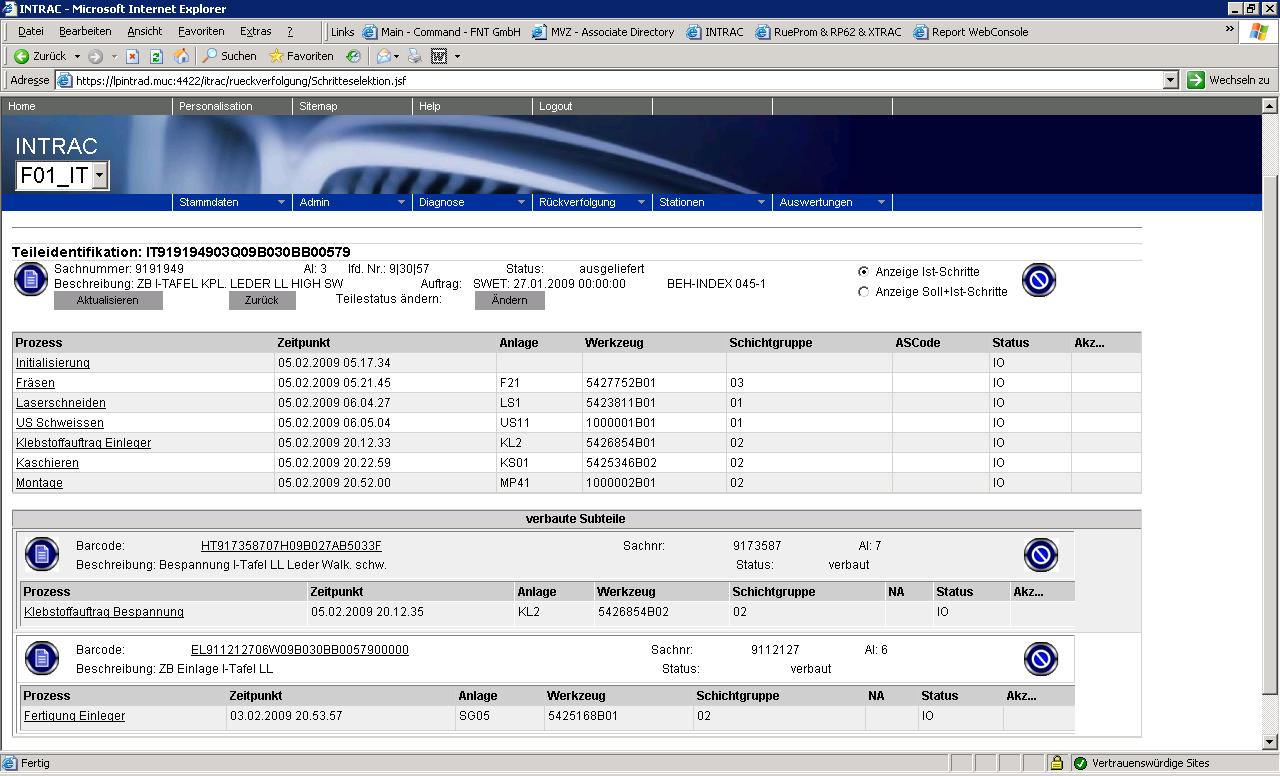

INTRAC hereby especially guarantees the inflow of job orders, capture of operating data, component tracking and process security.

The documentation and archiving of safety related airbag data is a legal requirement.

The basis for INTRAC was the RP62 system, which is already being used successfully in Wackersdorf.

Complete refactoring of predecessor RP62

This system was subjected to a complete re-factoring, to conform to current software standards (JSF, JPA) on the one side and increase the maintainability on the other.

On the other hand the system had to be made fit for the future, so that new model lines could be incorporated without big changes (currently the 7-series is integrated, other models are planned).

Over and above that, many new functions were added, e.g. to be able to replace and re-write the transponder on which many of the important data is stored.

New standards and hardware security

Two big challenges emerged due to the seamless scheduling, manufacturing and delivery in sequence (an error can no longer be covered by a store, but rather very quickly leads to a tear off)

as well as the parallel change to the company wide SAP installation.

To avoid hardware errors, the application is run in a Linux cluster.

Data from 19 Systems visualized individually

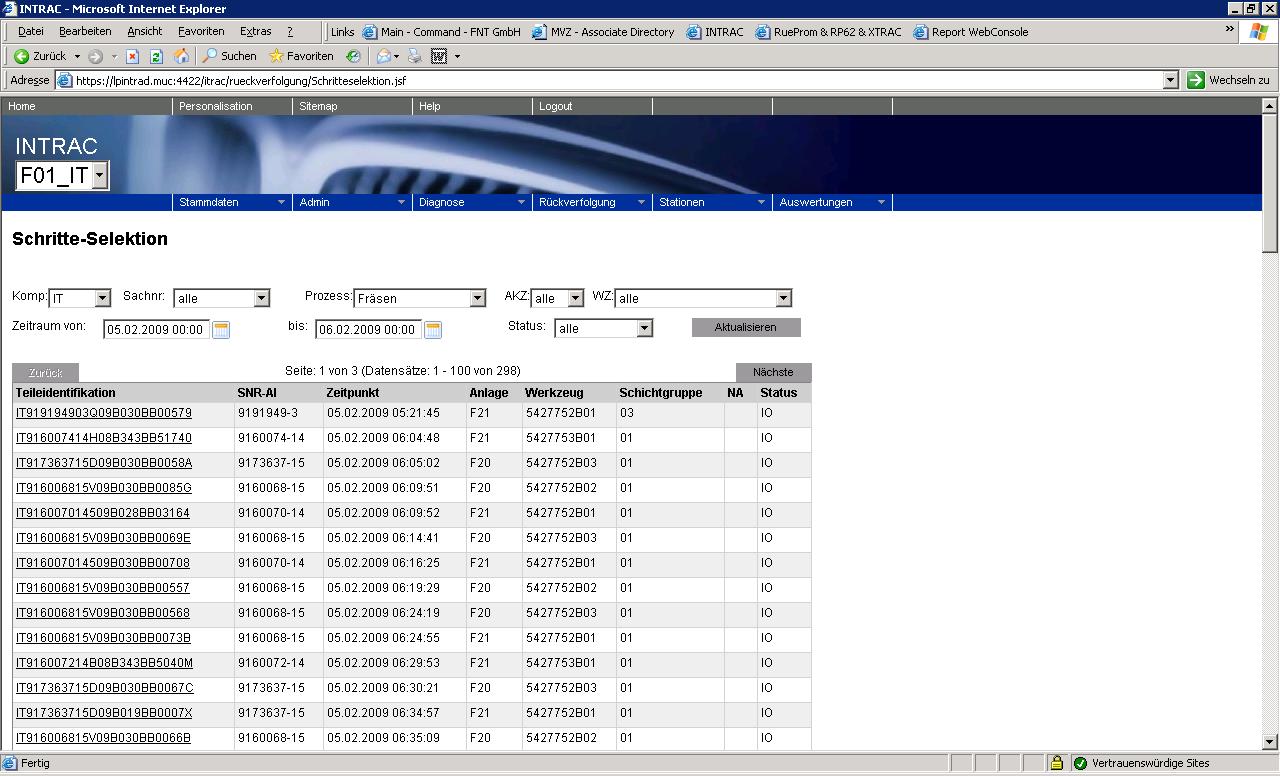

Currently INTRAC records process data, faults, operating modes, cycle times and volumes of 19 systems via send/receive.

To achieve this, SAR developed a S7 standard block, to keep costs to a minimum and to avoid repeated start-up problems.

The recorded data is visualized for the user in an intranet application. Here the user can also set up the system according to his own wishes:

- Set-up of the production systems (incl. connection parameters)

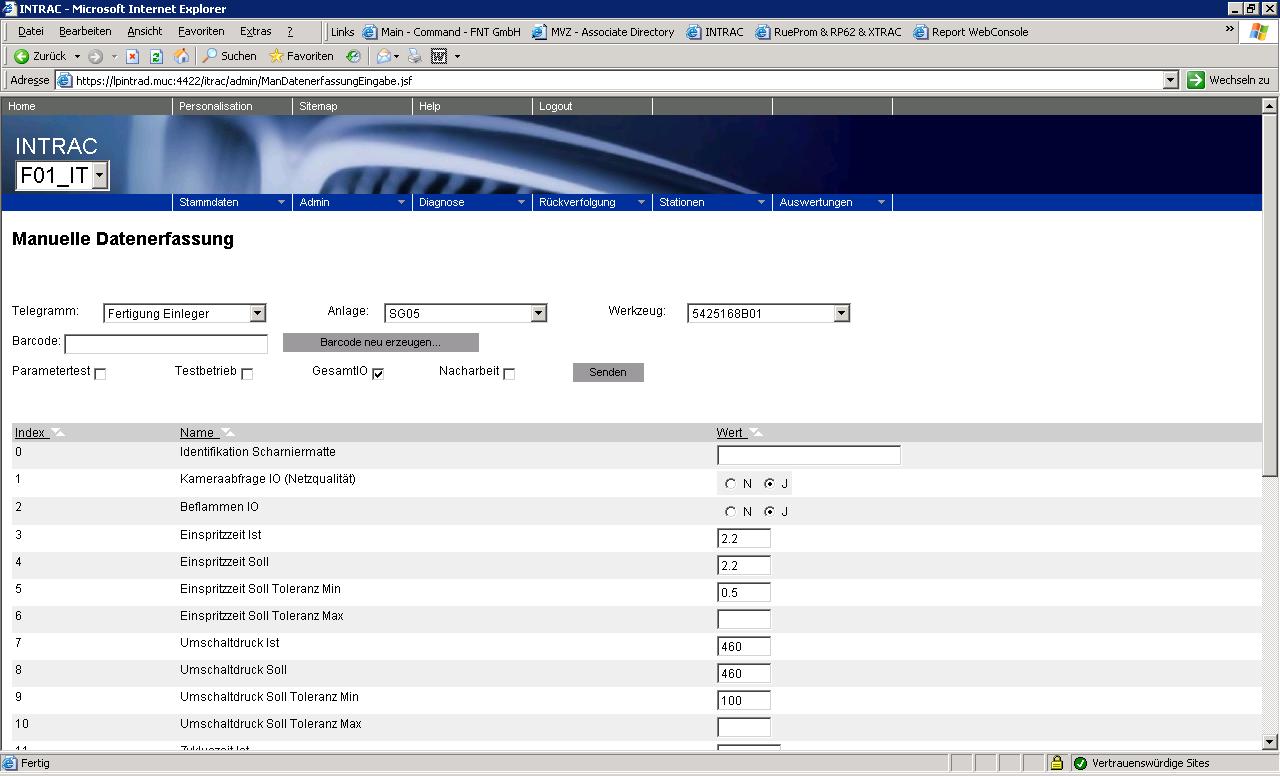

- Configuration of processes as well as their set point parameters

- Definition of the work plan (manufacturing sequence)

- Set-up of the required components and variants

- Import of error texts (faults)

- Definition of shift limits

- "Parameterization of telegrams from the controllers

In case of faults non-documented data can be re-entered or captured directly manually.

We thank BMW for the good co-operation during the complete run of the project.

For further information please contact us at

its@sar.biz