SAR Elektronic GmbH in Dingolfing has over 40 years of experience in the field of AI as well as digitalized and automated industrial systems. Its success is based on the wealth of ideas, performance and creativity of its more than 700 employees worldwide - now also in the field of intelligent service robotics.

"all about automation", the renowned regional trade fair for industrial automation, will open its doors in Straubing on June 26 and 27, 2024. As a compact, competent meeting place, the trade fair is characterized by its clear focus on automation and smart production technologies. It offers a unique platform for exchange between experts and practitioners from the entire spectrum of the automation industry.

This May, Orlando, Florida, will become the center of the plastics industry as NPE2024 opens its doors to the world's leading experts and companies. SAR, as a global pioneer in the development of automation systems for the plastics sector, is proud to participate in this international industry gathering for the first time.

District Administrator Manuel Westphal visited the SAR company in Gunzenhausen together with the business development department of the altmühlfranken future initiative. He was able to gain an impression of the latest technologies in robotics.

The Process & Environmental Technology division is pleased to present two special innovations at IFAT in Munich. With more than two decades of experience and over 200 successfully automated incineration lines worldwide, we focus on sustainable improvements and the future of energy.

A high-level delegation from the University of South Carolina Upstate recently visited SAR Automation LP in South Carolina. This visit underscores the growing cooperation between academia and industry.

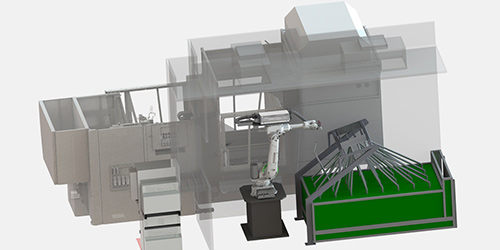

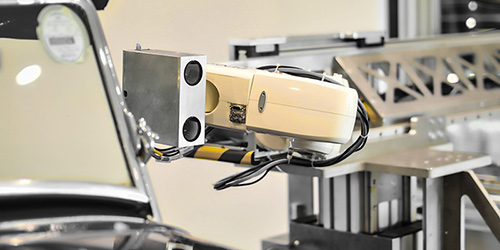

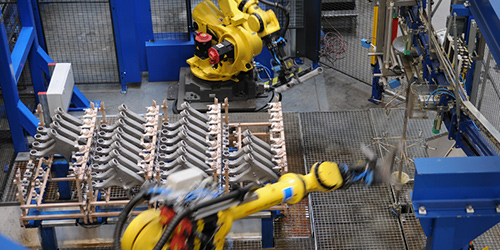

Falling numbers of skilled workers, reduced physical strain on employees and the enormously increased cost pressure in tire production: they are increasingly forcing producers to reorganize processes. At the Tire Technology Expo in Hanover, SAR is presenting a new generation of automation with robots.

SAR Dingolfing recently welcomed a high-ranking delegation from the University of South Carolina Upstate to its premises. This visit, organized by Landshut University of Applied Sciences, provided an important opportunity for an intensive professional exchange between the educational institutions and our company.

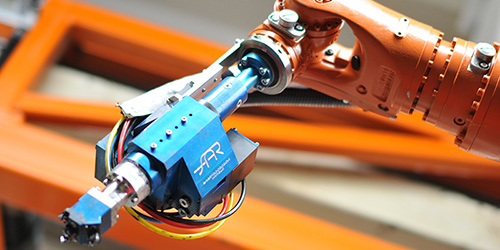

Fireguard pads are used in a new all-electric bus. New and familiar technologies come together to position these appropriately on the bodywork.

SAR supplied the entire electrical engineering for Germanys largest chiller in Heidelberg on behalf of E.ON Energy. The cold generated is used to supply the university, the university hospital, the neighboring institutes and research facilities with cold water.

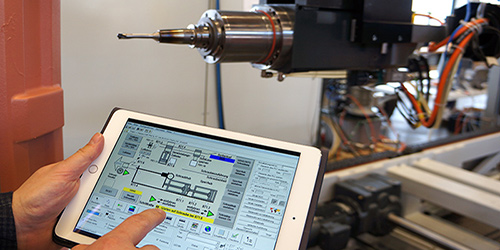

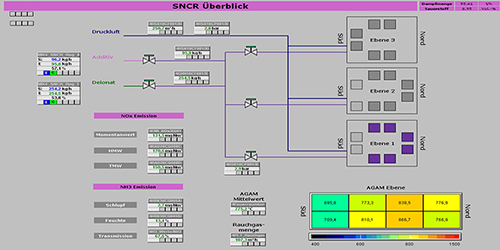

In 2024, SAR is taking its proven systems to a new level. In close cooperation with our partner Erium, we have successfully integrated artificial intelligence (AI) in the form of machine learning algorithms into the plant control system and brought it to market maturity.

FAKUMA, one of the most important trade fairs for the plastics industry, showed a positive mood this year despite the sometimes difficult economic situation in the plastics industry.

The increasing cost pressure in the industry requires new solutions and innovative approaches.

As part of the SAR Group, KNEXT offers efficient automation solutions for the catering and hotel industry. We are rethinking the future and delivering unique guest experiences through our technology.

On the way to climate neutrality by the year 2050, the city of St. Gallen is pursuing the goal of completely eliminating fossil fuels from its district heating supply as well.

SAR-Firing Technology looks back on a very successful and eventful year 2022 including insights into our research and development as well as cooperations.

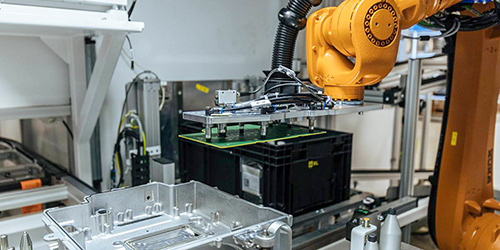

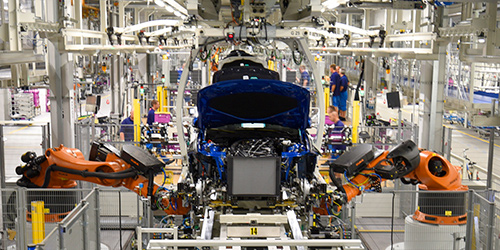

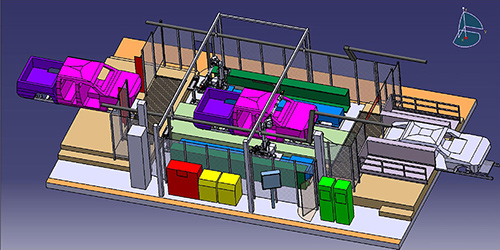

SAR programmed 15 controllers and 68 robots to ensure smooth assembly of the battery tray for the new, all-electric iX1.

This is a multi-type plant where battery trays for both hybrid and all-electric vehicles are assembled.

SAR Plastics Systems and ima-tec were represented at the leading plastics trade fair "K2022" in Düsseldorf with their own booth.

This year, May to July has seen a concentration of all events that, due to Covid, should be implemented in an "as low infectious as possible" period. SAR was present at many events.

SAR signed a system partnership with VIDEC for their product IRMA at IFAT in Munich in June.

IRMA protects production plants through anomaly detection and intelligent alarming.

A personal exchange at IFAT in Munich provided insights into the latest topics such as the digital simulation of power generation plants with the help of a digital twin or the protection of critical infrastructure through anomaly detection.

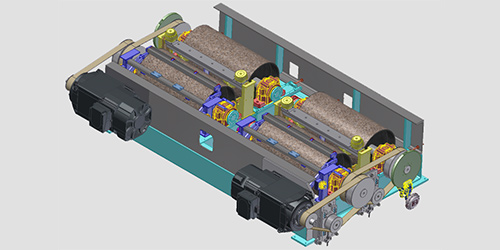

With the help of 11 KUKA robots and 17 HIRATA screwdriving robots, SAR has developed a fully automated, scalable production line for the core component of the electric car.

KNEXT and SAR participated at the the GITEX Technology Week in October under the "FUTURE of RETAIL" category, as a technology partner of the public UAE telecommunication group ETISALAT. The participation was tailored around the pre-launch of KNEXT's brand new fully autonomous premium coffee shop, which was developed by SAR in just 10 months.

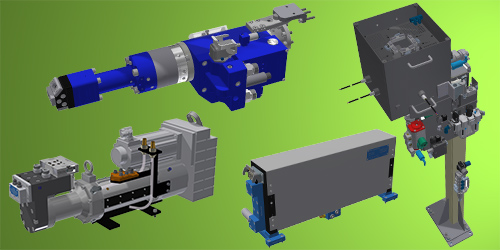

Lasers without protective enclosures, autonomously adaptable conveyor technology and modular tray stackers are some of the SAR products originally developed for the plastics industry, that have now been standardised across industries.

In spring, SAR South Africa donated a number of used but well-functioning notebooks to the youth organisation "Youth Sports & Finishing Academy" as aid for orphans and young people originally from Mozambique.

One of SAR Environmental Technology’s most extensive projects of recent years was successfully completed in winter 2020/21 with the seventh and final conversion phase of the Baar-Ebenhausen hazardous waste incineration plant.

A replacement plant for the existing waste-to-energy plant is being built in Stapelfeld. SAR was commissioned to supply the complete EI&C and control technology.

SAR can still assert itself as a market leader in the field of combustion technology for systems with heterogeneous solid fuels.

Despite the pandemic, exciting projects, such as on the Isle of Man (UK), were completed.

SAR was commissioned by Standardkessel Baumgarte to supply the electrical and control technology for a new gas-fired steam generator on the premises of DOW Benelux BV in Terneuzen (Netherlands).

From 2017 right up to the present day, MINI in Oxford has been renewing robot cells time and again, which we equip with SAR’s own developments.

MINI has seen the expectations set in its specifications "met and even exceeded".

Erium GmbH is a software company based in Garching near Munich, that uses artificial intelligence to optimize processes with its "HALerium" software.

Already taken for granted in IT and now also in use in plant construction: professional remote support through video AR glasses.

Strictly speaking, the headline is not exactly accurate, as it was the control system (thus the “brain”) of the incineration line 2 which was replaced at AVA in Augsburg.

The deadline for the migration to a new control system was met despite difficult circumstances.

SAR Environmental Technology is dismantling a pilot plant funded by the Federal Ministry of Education and Research (BMBF) with a view to "upcycling".

SAR had supplied the entire electrical and process control technology for the pilot plant, which was operated from 2014 to the end of 2017.

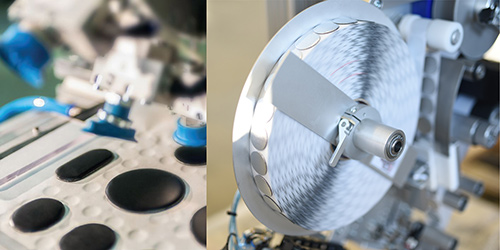

SAR is now enabling a manufacturer of medical laboratory products to meet the current massive increase in demand for materials for testing in medical industry laboratories within 3 weeks, by supplying automation solutions on injection moulding machines.

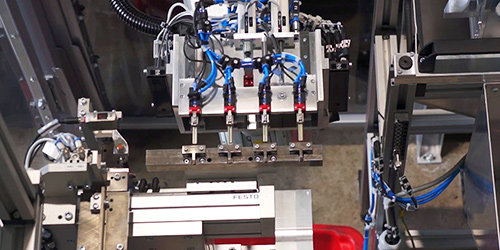

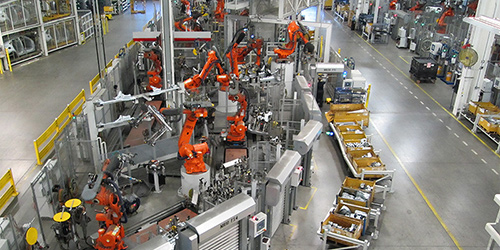

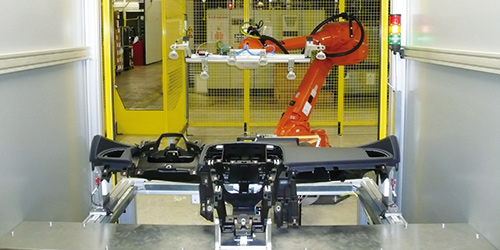

SAR has developed and implemented a fully automated cavity protection production line for BMW AG in Munich.

In this production line, car bodies are conveyed through initial work stations for the installation of equipment, then via foaming and car door protection systems, all the way to the first of the 3 cavity protection stations.

SAR is working together with Dynabook and Ubimax on solutions for manufacturing using Assisted Reality.

The data glasses can be used as smart helpers in production or also to support the maintenance of systems.

In cooperation with renowned manufacturers of adhesive pads, SAR has automated the process of applying pads onto openings in car bodies.

SAR’s “automated process of sealing holes” is characterised by significantly higher precision levels and process monitoring compared to conventional methods.

At Tire Expo 2020 SAR presented live the latest TIRE module from their automation kit for tire production.

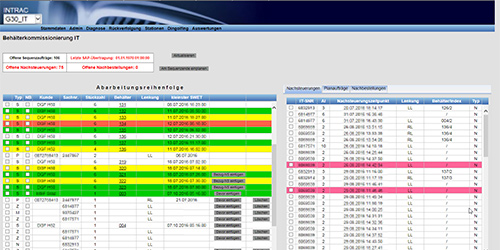

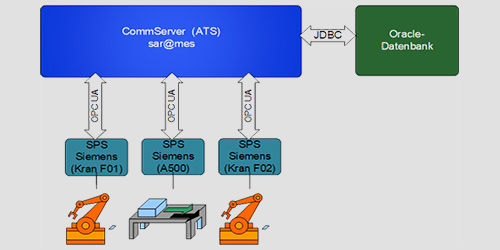

SAR increases plant availability in tire production by reliably connecting the controls with SQL databases.

Schmolz+Bickenbach AG is a steel company based in Luzern (Switzerland). SAR replaced their 30-year old warehouse control system at their site in Bronschhofen (Switzerland).

In recent years, SAR has established itself as the specialist for complex and time-critical control technology conversions in sector of thermal waste treatment.

SAR South Africa provided training for teachers at various colleges as part of a government program.

The long-term goal of the training courses is the introduction of a dual education system in South Africa.

SAR South Africa (SAR SA) has been awarded the contract for a project at Mercedes Benz in East London (South Africa).

The project will be realized in multiple stages over the next two years.

SAR has implemented systems for seam sealing of sheet metal overlaps in car bodies at the BMW plants in Regensburg and Leipzig with the 'value cell'.

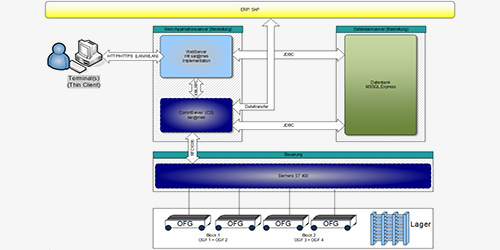

Intrac was originally developed by SAR for BMW in Dingolfing and Landshut and introduced in 2008.

The system was so successful that it has been further developed and expanded to this day.

By setting up a site in the Netherlands, we want to take account of the positive development in the Benelux region.

Our customers and contact persons should be able to make personal contact by a short distance.

In addition to an automation cell for water filter production, the SAR Group supplied a second robot solution for automated key production on a Sumitomo DEMAG injection moulding machine.

From 2014 - 2018 the logistics infrastructure of the WtE plant St. Gallen was renewed.

SAR Process and Environmental Technology was responsible for the planning and execution of the complete electrical and process control systems for this project.

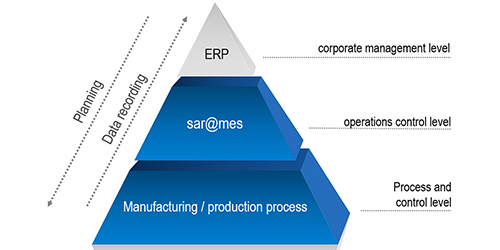

The MES (Manufacturing Execution System) of SAR IT Services has been extended by a special module for the plastics industry.

It was presented at an event of the "Plastics Network Franken".

Process and Environmental Technology is modernising the complete process control technology of the Baar-Ebenhausen hazardous waste incineration plant for GSB "Sonderabfall-Entsorgung Bayern GmbH".

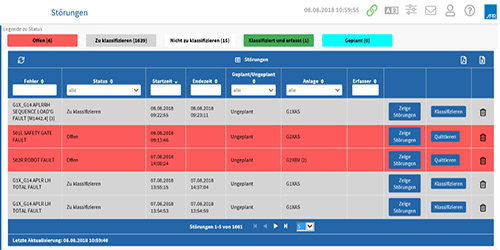

The WMU Bavaria GmbH was equipped with sar@mes to record plant downtimes and disturbances and to evaluate these disturbances. They are classified and assigned to escalation stages.

Im neuen Nexen Tire Werk in Tschechien laufen aktuell bereits 4 Reifensprühanlagen von SAR in Automatik.

Sie wurden innerhalb kürzester Zeit mit provisorischer Einspeisung im Trockenlauf vor Ort in Betrieb genommen.

Otto Fuchs manufactures aluminium windows and running rails for the construction industry using sar@mes as a control system for intralogistics.

SAR software is used from work preparation to dispatch, from process data logging to material flow control.

Following the successful completion of the first process and environmental technology orders at the refinery in Ingolstadt, SAR was awarded a "very good" rating by the customer Gunvor in a supplier evaluation.

At the BMW Group plant Dingolfing, the marriage line has been replaced by a new, innovative and extremely flexible assembly system.

Body shop standard extended to process engineering applications for the first time in the TIA Portal.

This included the entire electrical, instrumentation and control technology, but even more than the usual scope - starting from lighting all the way to telecommunication.

SAR implements Sinumerik controlled robot cell at Siemens Process Industries and Drives in Nuremberg.

SAR test stands are already widely used by many renowned automobile manufacturers. We are therefore happy to announce that now, for the first time, Audi in Neckarsulm has also decided in favour of a roller-test stand by SAR.

The existing bodyshell line at the BMW works in Spartanburg has had to be modified for production of the latest versions of the BMW X5 and X6.

A new, promising dispensing unit was developed by joint engineering between customer, dosing and mixing technology as well as automation.

At BMW's plant in Dingolfing one of the longest CDP dryers (CDP = cathodic dip painting) in the world was built. SAR supplied it's control system.

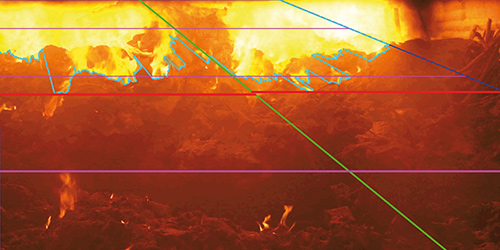

The new 'SAR fire length control' intelligently detects the so-called burnout line. This is used to derive the absolute fire length.

Due to a tightening of the NOx limit values for waste incineration plants and biomass power stations, SAR developed a control system for SNCR flue gas cleaning systems.

With SAR's mobile test system for optical feature testing, the quality of head-up systems can already be tested in prototype development or in the pre-series phase.

The Volkswagen commercial vehicles division has automated the fine seam application in the production of the new VW Amarok and Porsche Panamera in Hanover.

Volkswagen AG has introduced a pilot project in Europe's largest paint shop in Wolfsburg to replace the manual fitting of insulating mats in the passenger compartment with a spray technique.

SAR South Africa worked on an underground coal mining project as part of a research and development project commissioned by Anglo American.

Plastic components for the current SUVs from VW and Porsche are very pronounced in terms of space with a wide variety of variants. SAR meets the associated manufacturing requirements.

The new robot measurement cell at the BMW plant in Dingolfing is able to acquire and measure complete vehicles with high accuracy.

In order to improve quality and save materials and weight, the VW Wolfsburg plant invested in new control and application technology for the UBS area. In the 3 UBS lines, the Golf, Golf Plus and Tiguan are sealed.

As general contractor, SAR supplied a conveyor and handling system for the interlinking of cast parts (A-arms for car chassis) to the Georg Fischer company in Friedrichshafen.

An A-arm (or trapezoidal-link) is a component of the suspension in a modern motor vehicle.

SAR has put a new fork lift calling system into operation in the press shop of BMW's Dingolfing plant.

The task was to set up a lean and efficient system which, with easy to understand and intuitive operation, creates a high degree of transparency for all areas involved in the process.

Johnson Controls in Lüneburg utilizes ten Ethernet cameras based on GigE technology to test up to 50 specifications in three variants of a passenger vehicle cockpit.

A testing cell like this ensures a 100% quality control.

With driver assistance systems, like for example head-up displays, fitment faults can cause a large variety of picture faults.

The testing systems from SAR find these faults reliably and fast.

SAR developed a complete MES-system for BMW Landshut and BMW Dingolfing at the dashboard and leather skin production facilities.

The system represents the vertical connection between the production level and the ERP system.