Fireguard pads are used in a new all-electric bus. New and familiar technologies come together to position these appropriately on the bodywork.

SAR has been successfully using the automatic hole sealing process for several years now. In short, adhesive pads are automatically placed on openings in the body shells.

We have now literally taken this process to the next level.

The setting heads with rotating punches used for the first time are new.

The hall floor also had to be opened up. The reason for this was that the car bodies run in a hanger and this level is above the application cell. The application robots, initially 2 and later extended to 4, were thus able to reach the vehicle perfectly and apply the heat pads.

These heat pads prevent the flames or smoke from entering the vehicle interior too quickly in the event of a fire. In contrast to normal pads or plugs, the special heat pads have a significantly longer fire resistance.

Despite the challenge, the project was successfully completed on time after 5 months.

For more information please write to us at

ofs@sar.biz

Can be optionally expanded from 2 to 4 robots

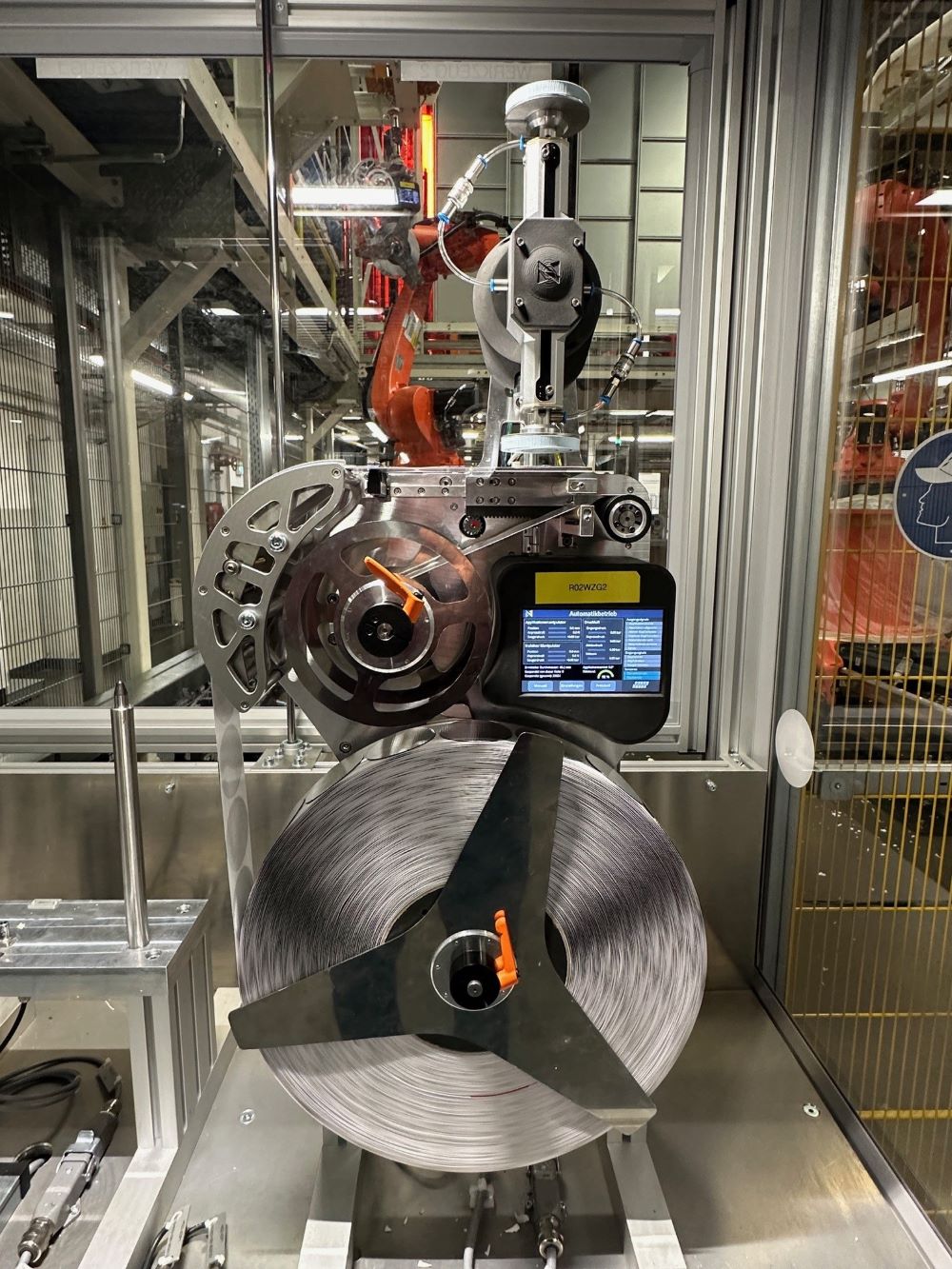

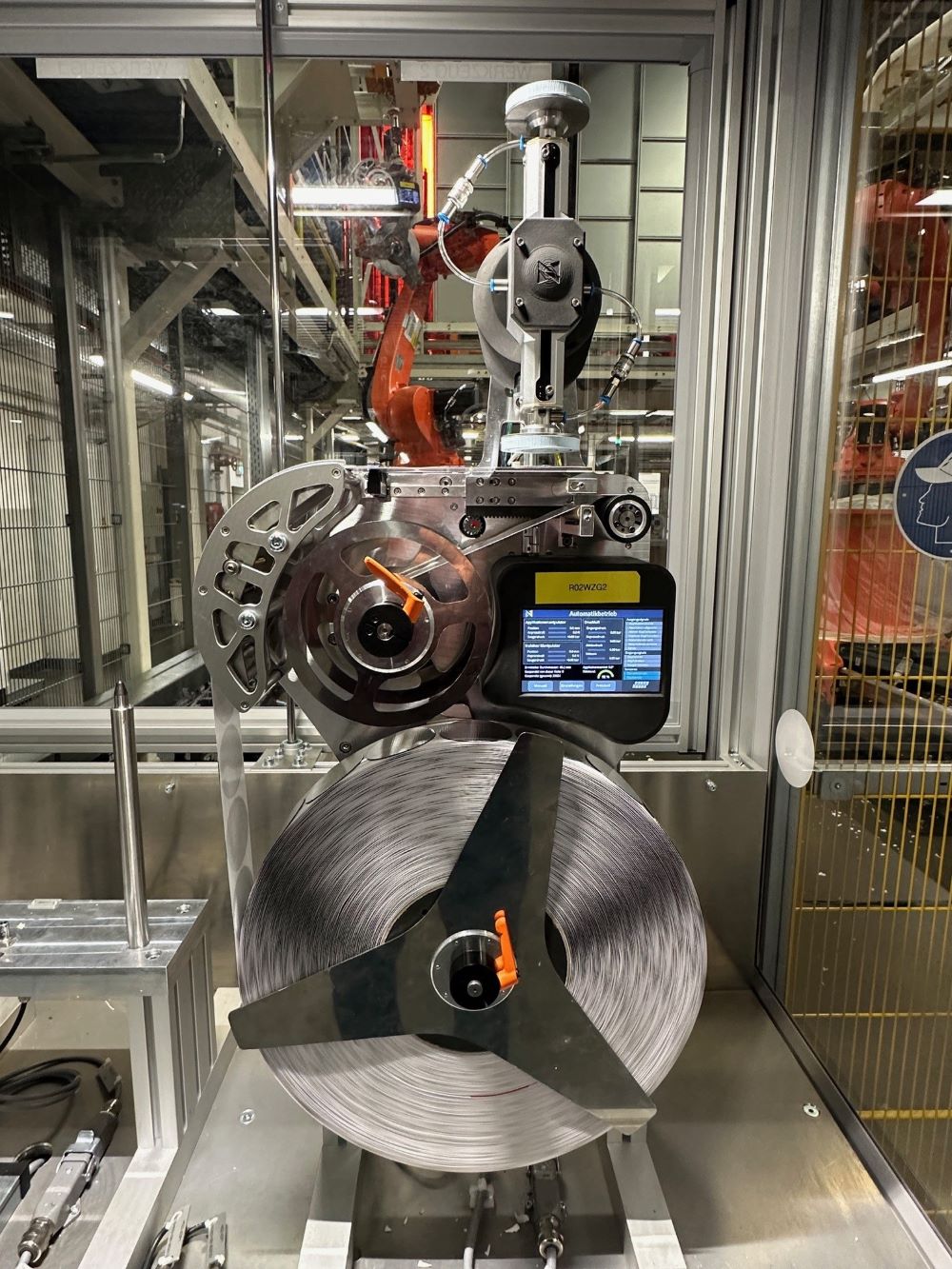

Role of the heat pads on the robot

Example of applying the heat pads