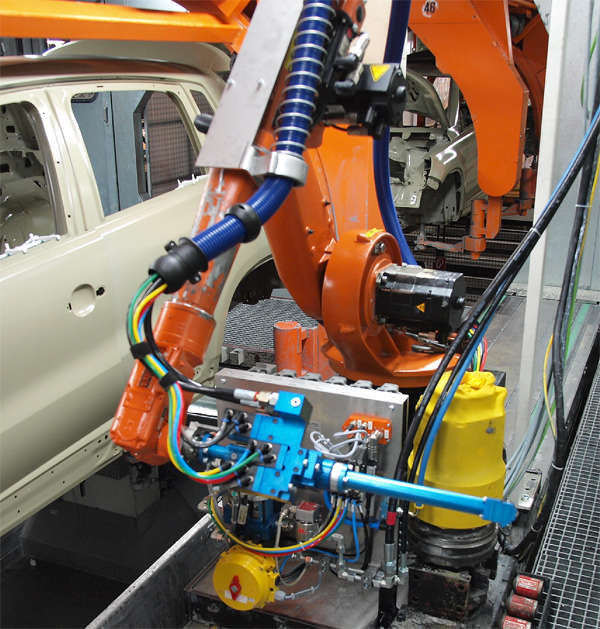

The SAR flat-stream application - an automatic joint, bead and area sealing system has been in action in the VW factory in Wolfsburg for a couple of weeks now.

To ensure better quality, use less material and have less weight, VW invested in a new control and application technology for their Wolfsburg plant.

The Golf, Golf Plus and Tiguan are sealed on these 3 UBS lines. The goal of these changes was the increase in quality together with the reduction in used material.

SAR scope of supply in Wolfsburg

Conceptualisation, simulation, construction, manufacturing, delivery, commissioning including safety analysis and total CE certification of the robot cells.

Characteristics:

- 35 controllable SAR dosing systems Type SV-16

- 3x upgrade of old Siemens S5 PLC's to 3 new line controls based on Siemens S7, including Intouch visualization systems

- Adaption of the application booths, the booth technology, the material supply and the steel work

- Integration of additional robots and SAR dosing systems

Praise for SAR

Mr. Bernd Herold from the VW paint shop's planning division in Wolfsburg commented to SAR project manager Bernd Kretschmer:

"The company SAR proved themselves with extremely high competence and excellent service during this PVC application project.

Technical guidelines and constructive layout of the complete systems technology helped by enhancing especially the quality and productivity and thereby the achievement of our goals.

The set time frames were all attained and kept and problems were solved in the shortest possible times by means of dedicated measures."

Further projects are already running

The integration of further robots with SAR dosing systems were already ordered and are currently being implemented.

For further information please contact us at

ofs@sar.biz