Transparency for production, processes and products - these are the content goals of "Industry 4.0".

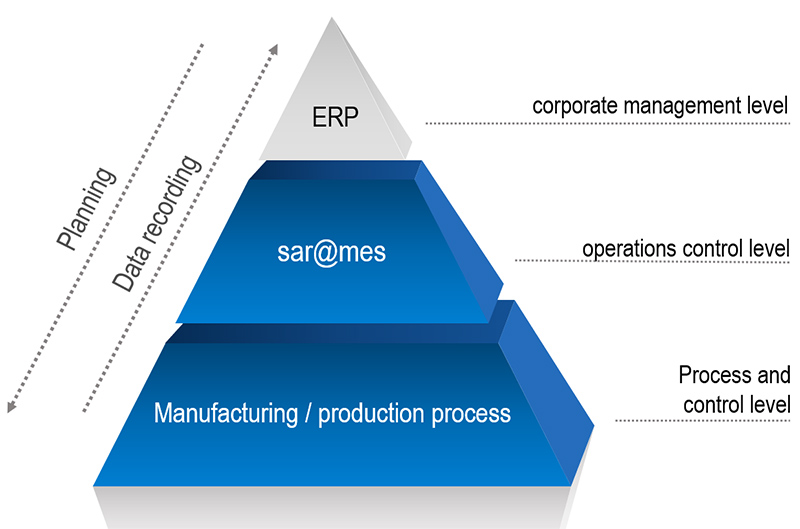

MES stands for Manufacturing Execution System and is used to record process data from production.

It is primarily used as a production planning and process control system.

Increasingly, this process information is assigned to the product via the MES and attached to the component via labels.

sar@mes

SAR has been developing sar@mes for 18 years, primarily for OEMs with complex and multi-layered process levels.

With the Industry 4.0 campaign, this data collection and processing is becoming increasingly important for small and medium enterprises.

The advantages lie in being able to optimally utilize production capacities, to use the relevant data to optimize processes and cycle times, and to increase quality in a targeted manner by linking them to the component.

sar@plastics

For this reason, sar@mes was modularized and linked to SAR automation knowledge from the plastics industry.

Based on this, a modular MES variant was developed that can be cascaded depending on the size of the company: sar@plastics is optimized for the complete process chain in the plastics sector.

Working Group Automation

Within the scope of the working group "Automation" of the "Plastics Network Franken",

Stefanie Eisenreich of SAR first explained the software modules necessary specifically for the plastic processes, from material delivery to the plastic processing to intra- and goods logistics.

Advantages for management

She visualized the benefits for management, operators and maintenance teams.

The latter are increasingly confronted with

preventive maintenance and

fast troubleshooting and can thus contribute to optimal

OEE key figures.

Final, she demonstrated proven methods for implementing an MES with the best possible human resources within a manageable timeframe.

For further information please contact us at

kss@sar.biz