Reduces CO2 and improves the acoustics

Volkswagen AG has introduced a pilot project in Europe's largest paint shop in Wolfsburg to replace the manual fitting of insulating mats in the passenger compartment with a spray technique.

The aim of the SDM robotic stations is to ensure high quality, reproducible and economic soundproofing of the bodywork.

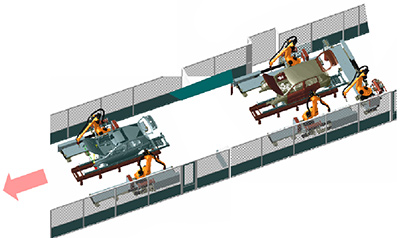

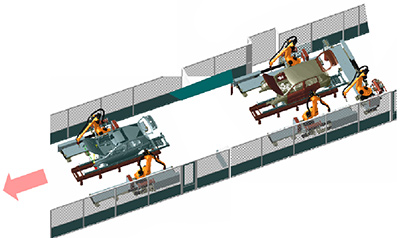

This new production stage has been successfully introduced into the UBS 2 sealing line. The required coating for the Golf, Golf Plus and Tiguan models is applied in a two-stage process using 5 robots.

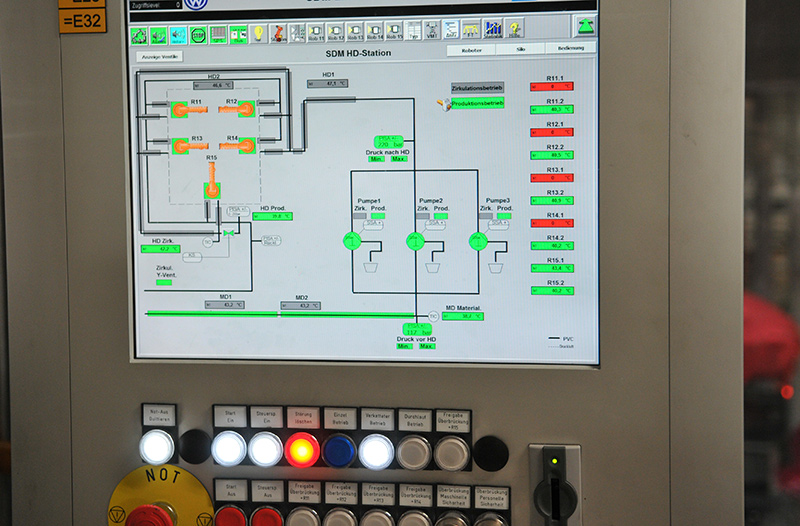

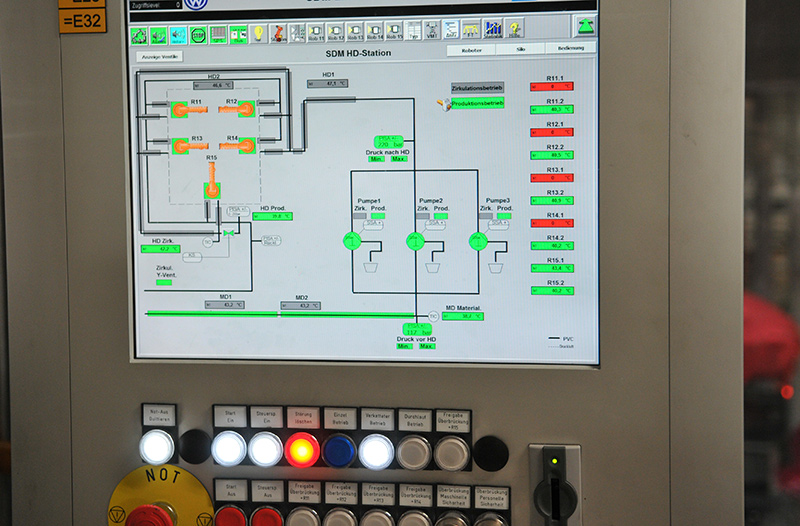

Modern control systems and dosing technology with materials supplied through silo technology

The automated application of soundproofing materials makes use of the most up-to-date control systems and dosing technology.

A rubber-based material is used for the insulation, which is both easy to use and particularly environmentally friendly.

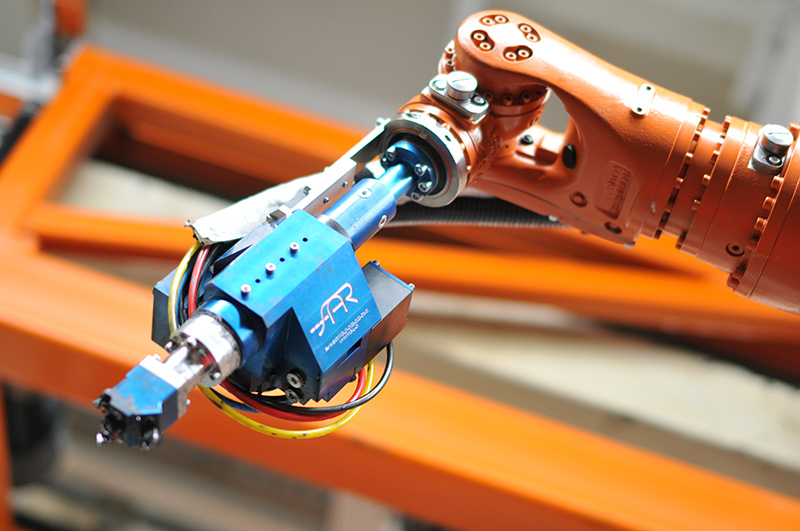

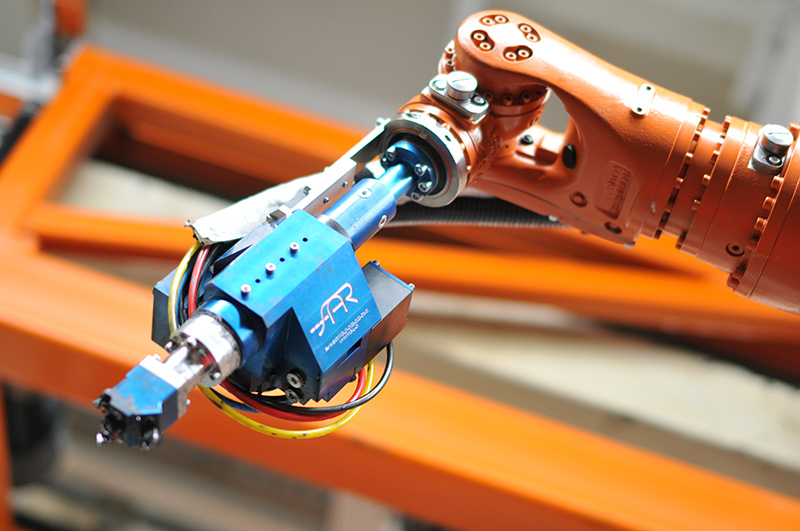

The insulation is applied at 40 degrees using SAR developed dosing technology and the new SAR applicator pistol.

This dosing system and the applicator pistol have been successfully implemented in the paint shop more than sixty times.

A further special feature is the fact that, for the first time ever, the materials are being supplied throughout the plant by means of silo technology.

VW is the first car manufacturer to have the rubber material delivered in temperature-controlled tankers (with a capacity of 20 tonnes) rather than in 1,000 l containers.

SAR implemented this pilot project using Quantec series KUKA robots, fitted with the new C4 control system. The supply technology was adapted by the customer.

As a general contractor, SAR supplied the new cell controllers for the robotic cells, incorporating modern visualisation and material supply.

Weight reduction and improved acoustics

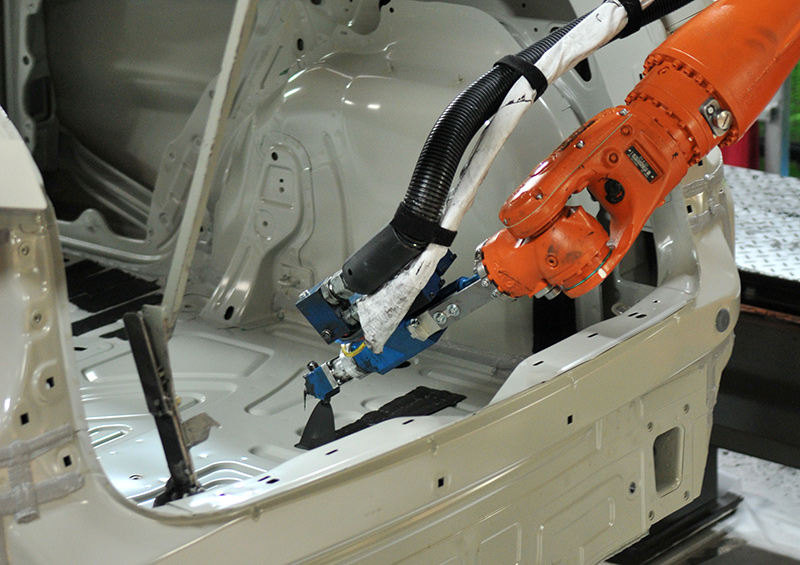

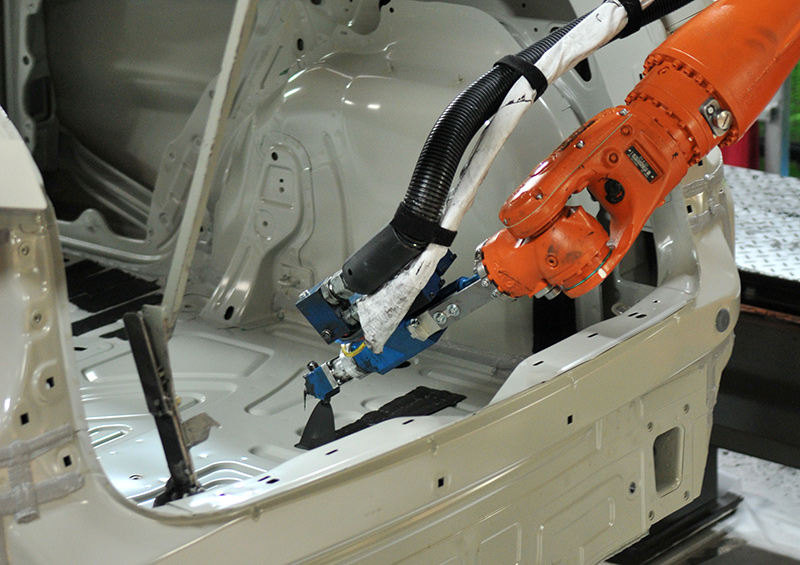

Application for all models requires no handling; there is no need for the doors or tailgate to be opened specially.

Precise programming for each model and the high level of accuracy in repeating the process result in a weight reduction of between 0.4 and 1.4 kg per vehicle compared to those with standard insulation.

The result: a reduction in CO2 levels and improved acoustics in the car interior.

The pilot plant meets VW's exacting standards and the results of the application also meet the VW quality standard.

As a result, 3 further lines are now being modified. SAR was able to secure the contract for this. The next line will start production in April 2013.

For further information please contact us at

ofs@sar.biz

Applicator pistol

Application of the sprayable insulation

The finished application

Visualisation of the line

Overview of the line control system

Line simulation