The upcoming tightening of the NOx limit values for waste incineration plants and biomass power stations, as well as significant market demand arising in this context, were the reason to develop a control system for

SNCR flue gas cleaning systems.

Many flue gas cleaning systems are constructed as so-called selective non-catalytic reduction plants (SNCR).

In contrast to the SCR process, the SNCR process does not work with a catalyst, but uses the injection of reducing agents (ammonia water, urea) into the hot flue gases, and the resultant chemical reaction, to eliminate harmful substances.

Replacement of the SNCR control system instead of expensive modifications

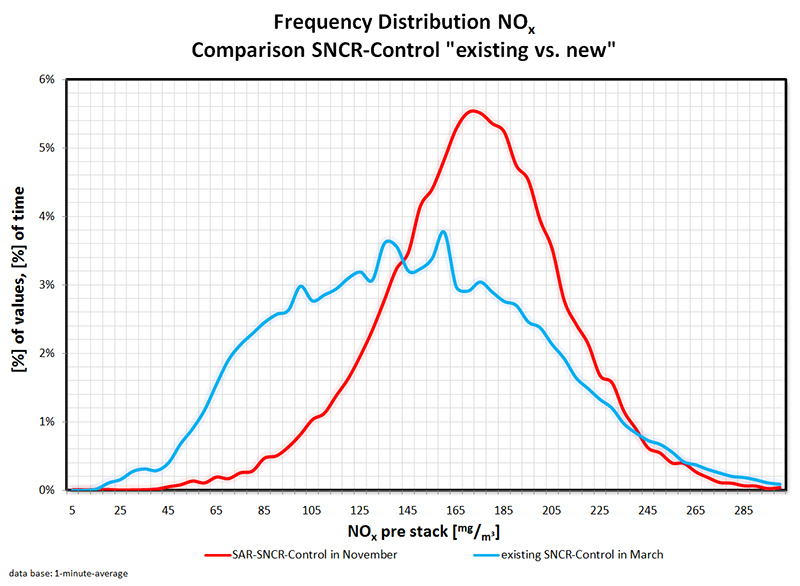

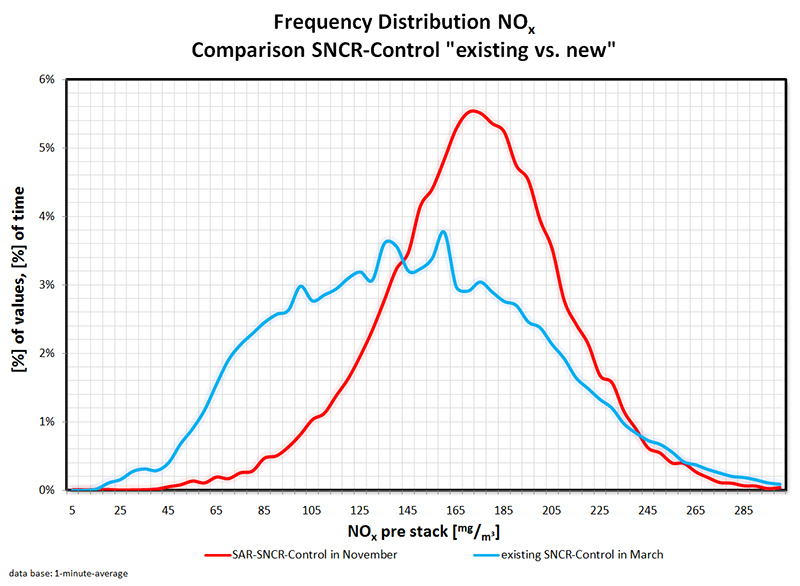

A good option - apart from extensive and expensive modifications - to meet the more stringent NOx limits with a SNCR flue gas cleaning system, is to replace the existing control system with the SAR SNCR control system.

This has a range of innovative functions and makes a lasting positive impact on the process of flue gas cleaning.

The SAR SNCR control system incorporates all the features of an innovative, open and comprehensive control concept. It offers the opportunity to meet the required limits and to reduce the use of resources.

For further information please contact us at

put@sar.biz or take a look at our flyer

SNCR control system by SAR

SNCR control system by SAR

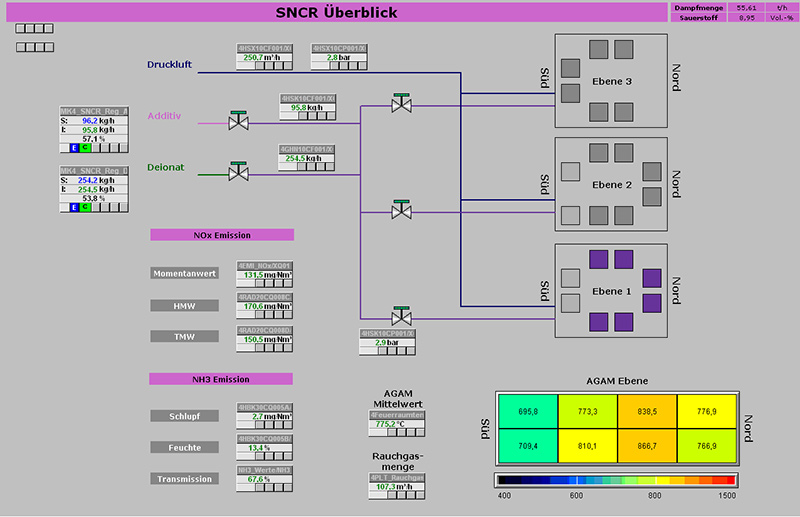

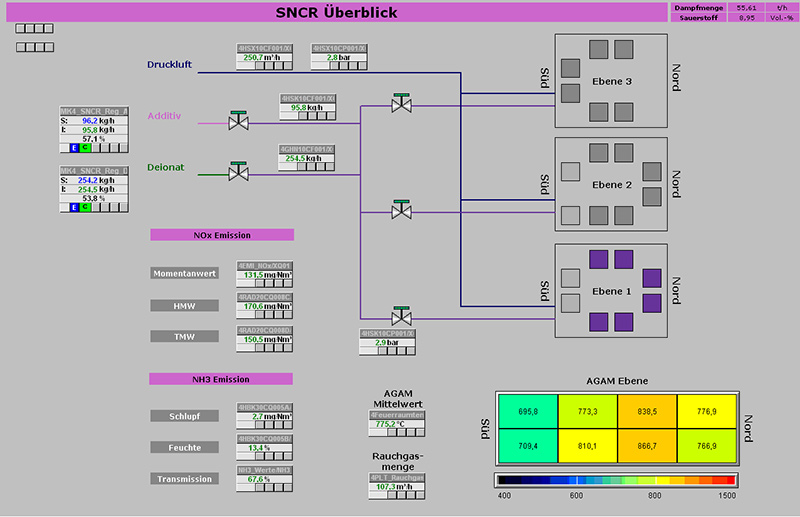

SNCR control system (project example)

a higher control quality and as a result a higher NOx set point combined with lower additive consumption is practicable