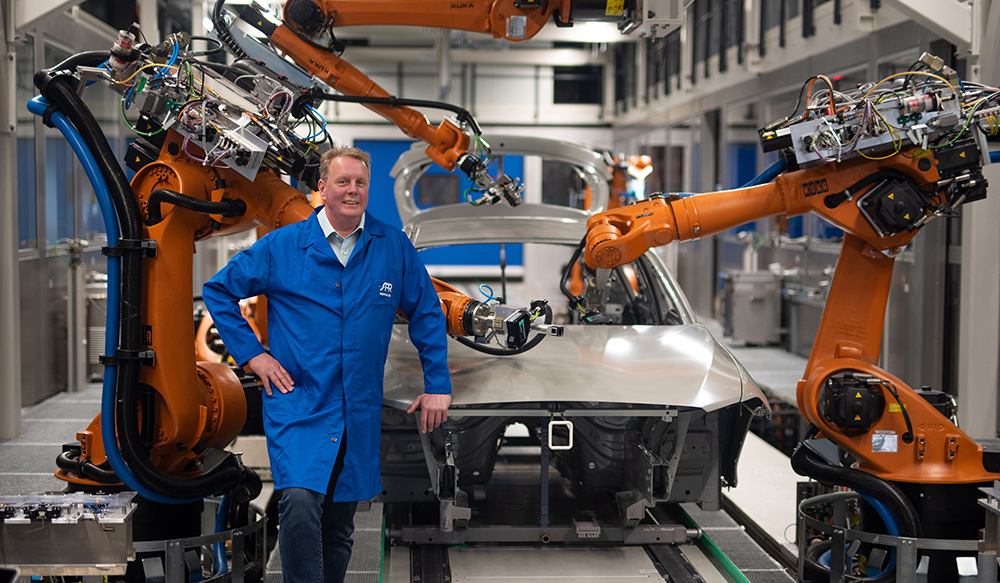

SAR has implemented systems for seam sealing of sheet metal overlaps in car bodies at the BMW plants in Regensburg and Leipzig with the 'value cell'.

Focus on the quality of seams

In the first period after the conversion to visible seams, these were applied without surveying.

The new cells focus on the quality of the seams.

The cell measures the sheet metal overhang and spacing before the application.

After application, the position and dimensions are checked for quality assurance purposes.

This results in a consistently high quality of the seams.

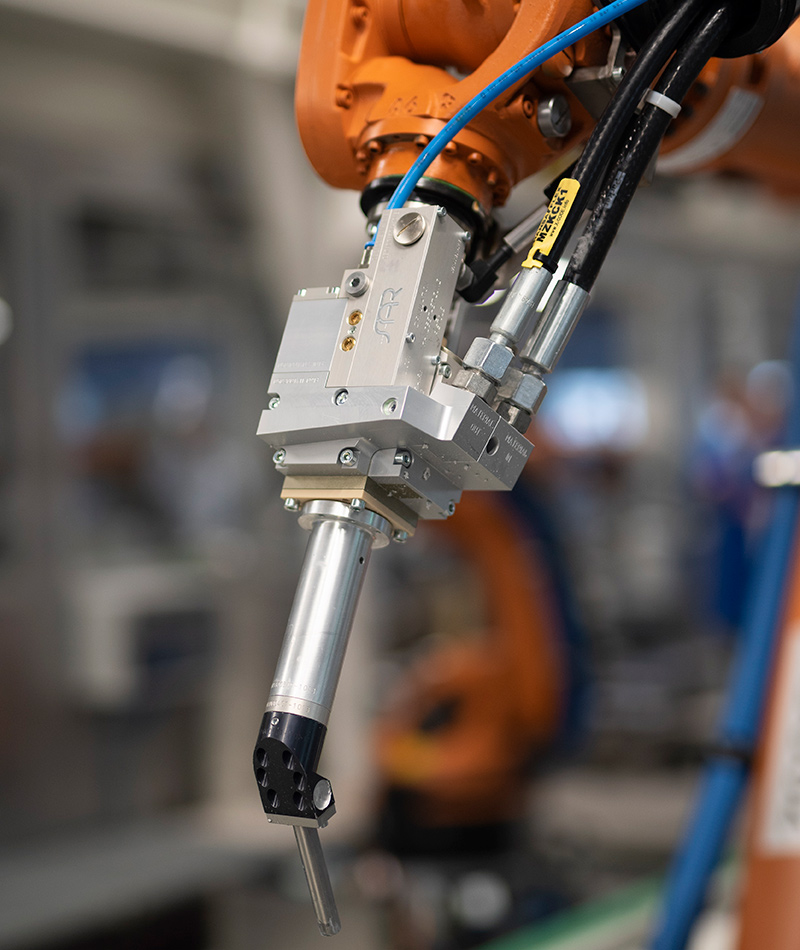

Shorter distances due to dosing unit on third axis

The installation of the dosing unit on the third axis of the robot shortens the path to the applicator.

The tube length is reduced accordingly and the tube breathing effect is reduced considerably, with positive effects on the seam quality.

High flexibility for model series

Depending on the vehicle model, the appropriate application nozzles can be changed using nozzle changing systems.

For further information please contact us at

ofs@sar.biz

Video "value cell"