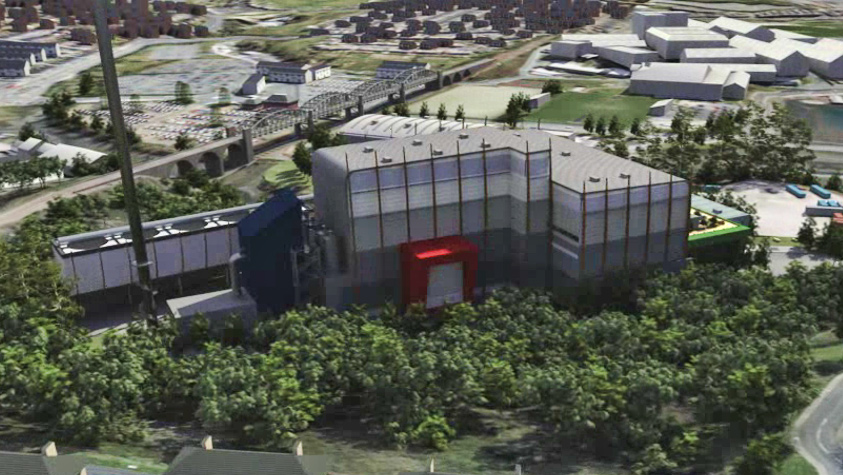

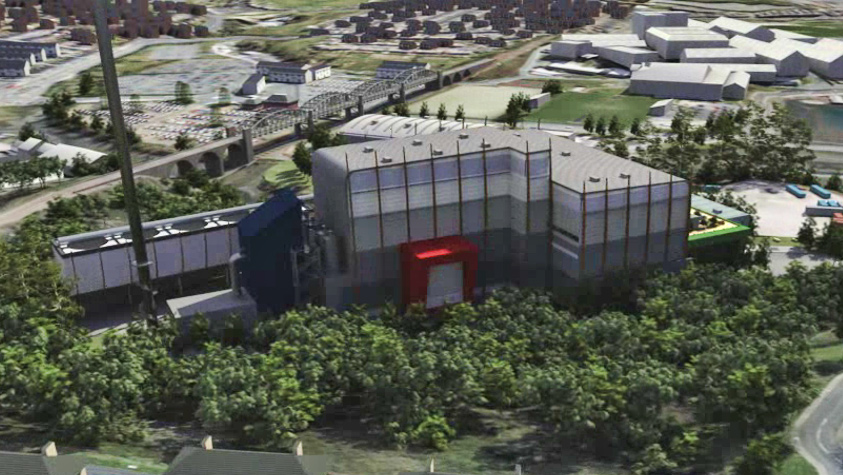

Just in time for the ceremony of SAR's 30 year anniversary, we have received official acceptance for our achievements in the new construction of a waste incineration plant in Plymouth, England, one of the largest projects in the history of SAR.

SAR was chosen as a contractor by MVV Umwelt (environment) in Mannheim for the implementation of the electrical installation and control technology.

This included, among other things, the entire electrical, instrumentation and control technology, but even more than the usual scope for SAR - starting from lighting all the way to telecommunication.

In addition, SAR supplied the combustion control system as sub-supplier to Baumgarte Boiler Systems as well as the control system to Sutco for their baling plant.

The project took SAR four and a half years to complete - one year of design and planning and three and a half years of implementation.

A Sustainable Waste Disposal Concept

Sustainable energy production from domestic and industrial waste is becoming increasingly important. It is for this reason that in 2011 MVV Umwelt (environment) in Mannheim, a subsidiary of the energy company MVV Energie,

together with South West Devon Waste Partnership (SWDWP) signed project contracts for the construction of a waste-to-energy plant in Plymouth in the southwest England.

The high efficiency power station will turn approximately 245,000 tons of waste per year into environmentally friendly electricity (22 megawatts, which can provide approx. 37,000 4-person households with power) and into heat (23 megawatts by using process steam).

With maximum district steam supply, the plant will reach an efficiency rate of 49% - twice as high other British plants at present.

The heating energy plant provides a sustainable waste disposal concept and replaces the previous landfill system. Furthermore, the waste is used to generate energy thereby replacing fossil fuels.

The plant will generate power for the public electricity distribution network and provide power and heat to the local naval base.

This will result in a considerable cost reduction for the Royal Navy at their oldest and largest naval base in Europe. The municipalities will also profit from low waste collection fees.

SAR's Scope of Supply and Service

Within the project, SAR was awarded the contracts for the entire electrical installation and the combustion control system.

As a contractor, SAR was responsible for engineering, project management, supply, commissioning & optimisation as well as cabling and installation.

Besides the key competence of control technology, SAR provided many more components, from access control to safety technology and even lighting:

- Main transformer (30MVA) including voltage regulators

- 5 auxiliary transformers up to 4MVA

- Medium and low voltage switchgear (11kV, 400V, 690V)

- Emergency diesel generator (1MVA, 11kV)

- Redundant UPS plant (2x 100kVA)

- Frequency converter (from 0.37 kW to 1,500kW)

- Control technology (5 highly available PLCs, 5 operator workstations)

- Process control system incl. a power plant library compliant with the VGB standards and codes (PCS7)

- Access control

- Fire alarm system, bunker fire monitoring, fire detectors for inert-gas extinguishing system

- Lighting, façade illumination, security lighting, emergency lighting, street lighting, process lighting

- Telecommunication systems, CCTV cameras, surveillance cameras (40)

- Sampling point (7 measuring sites)

- Automatic refill station for diesel fuel

- Design of the grounding and equipotential bonding system

- Complete lightning protection

- Combustion control system, fire length control

- Water cooled optical fire room cameras

- Redundant emission and raw gas measurements including automatic test gas supply system

Special Project Features

The power plant in Plymouth employs a high degree of automation compared to other power plants. The requirements in this project were therefore very complex. Furthermore, the scope of delivery included some very particular features.

Special steel-reinforced cables were used to increase mechanical protection. The strongest cable has a cross-section of 800 mm

2.

For communication purposes, 20 special cordless phones with emergency signals are provided in addition to the permanently wired phone systems.

For example, the phones generate an alarm signal if they have been in a horizontal position for a certain period of time, as the operator of the phone might be in an emergency situation.

A major part of the power plant's lighting is automated. For example, rooms will be dimmed when employees leave the offices, or the lights turn on when someone enters a room.

With a control, the façade lighting, which symbolizes the hull of a ship, can be changed into various colours.

Special cameras are implemented in the monitoring system for the fire room. They are water cooled and may be moved into or out of the fire room.

Another special feature is the automated waste unloading system. Up to 5 trucks can unload at the same time. The unloading process is controlled via a traffic light system and monitored with a camera system.

The gates to the waste bunker are controlled via induction loops and close automatically if no truck is present. Furthermore, the waste bunker is kept at negative air pressure.

Regarding occupational safety, the SAR employees were faced with the challenge that a combination of both European and British regulations (British Standards) applied.

A health and safety manager had to be appointed to deal with the intricate health and safety regulations.

Conclusion

With their expertise and their great dedication, all those involved have contributed to the successful implementation of this modern and high-tech project and to the satisfaction of

MVV Umwelt.

With this power plant project in Plymouth, SAR has again shown extensive know-how, experience, and the ability to provide comprehensive solutions also beyond control technology.

This proves again that SAR is well equipped as a competent partner to handle projects of any size.

For further information please contact us at

put@sar.biz

System simulation during the planning phase

Façade lighting in refuse bunker and boiler house area

Control room with distributed control system

Assembly of "ribs" on the waste bunker

Battery room for UPS (108 cells at 90kg/cell)

Emergency diesel 1MVA 11kV in the container with sound insulation attachment and exhaus silencer

Main transformer 30MVA

Auxiliary transformer in the transformer housing

Waste unloading hall with automatic gates