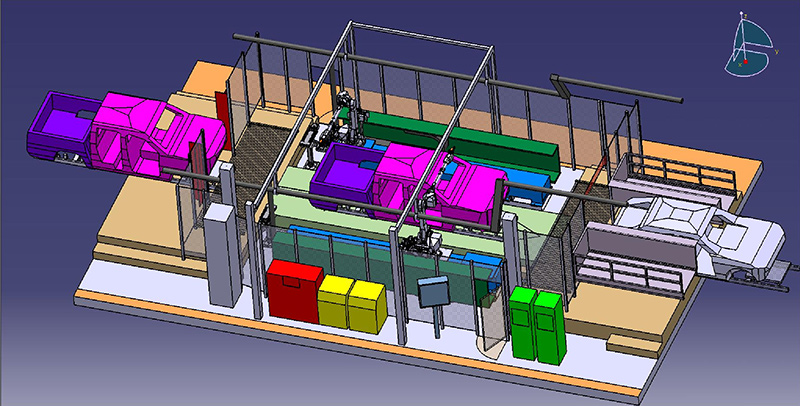

The Volkswagen commercial vehicles division has automated the fine seam application in the production of the new VW Amarok and Porsche Panamera in Hanover in two steps.

The first step was focused on sealing the so-called Cargobox, because of the extreme difficulty of accessing this area for manual application.

The second step also automated the application of the doors' interior folded seams and the back of the loading panel.

Multiple nozzles? No problem!

The automated fine seam application is performed using electric tandem dosing units for high-precision dosage, which in turn saves on material.

So-called multi-PVC is applied, which can be used for both area-wide applications and fine seams. It is considered to be environmentally friendly and can be easily processed.

The seams are applied with a delivery gun, which is equipped with a nozzle changing system. This allows for a large application range and nozzle varieties for use in hard to reach areas.

Another feature is the nozzle changing table for 10 different types of nozzles, to meet all application requirements in a single cycle.

SAR implemented this pilot project with Fanuc robots, equipped with the new RJ3 control.

VW standard exceeded

Because of the repetition accuracy obtained it is possible to achieve very high quality, which surpasses the high standard of VW in comparison to manual application.

All fixtures are applied without additional handling. In other words, doors and tailgate do not have to be opened separately.

Scope of supply

As the main contractor, SAR delivered the new cell control for the robot cells with modern visualization, the material supply and the application technologies as a complete system.

For further information please contact us at

ofs@sar.biz