Intrac was originally developed by SAR for BMW in Dingolfing and Landshut and introduced in 2008.

It was an MES in the "instrument panel and leather hide manufacturing" and established a vertical link between the manufacturing level and the ERP system.

Development milestones

The system met with great acceptance and interest and was therefore constantly further developed and expanded:

- from 2009, new series were integrated, a process which is still continued today

-

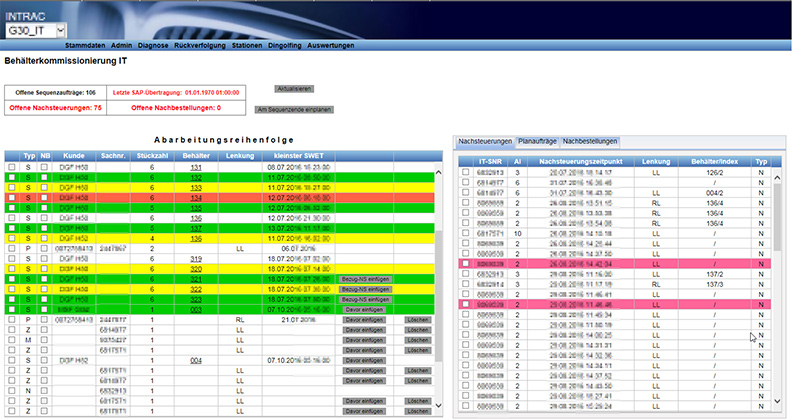

2010 Introduction of a database-driven logistics control system by INTRAC

Example: The sequence is determined by production. At 12 stations, different production steps are planned, prioritized, dependencies checked and controlled, depending on the customer order.

At each workstation, the employees receive all necessary information about the order and the configuration for the respective component that is currently being processed.

All production steps are logged and archived in a database.

-

2013 Switch from RFID to barcode

Starting in 2013, RFID chips in cockpits were gradually replaced by barcodes in the series.

The data and the production process for the component are not stored on the chip itself but exclusively in the database.

- 2014 Technology milestone: Switch to the Glassfish application server to reduce license costs for BMW

-

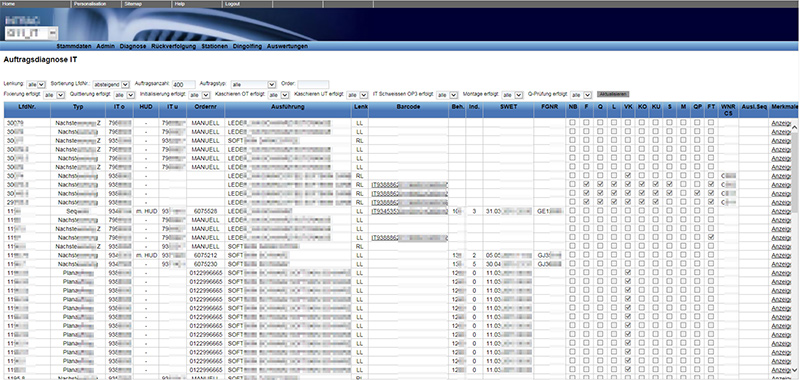

2016 Scrap recording and interface to SAP::

Since 2016, INTRAC has documented the committee and entered the booking details in the same application.

The master data posting is transferred to SAP in real time via an interface. INTRAC uses the IDOC technology as the interface.

- 2018 and outlook: Currently, the switch to new, modern technologies and design takes place via the PrimeFaces framework.

For further information please contact us at

its@sar.biz