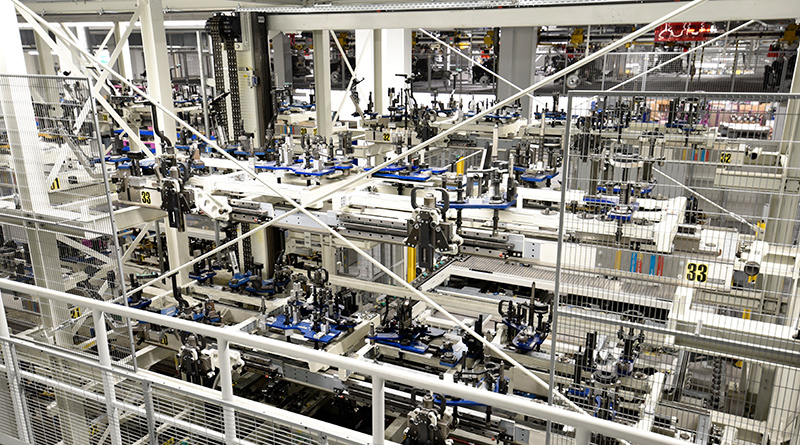

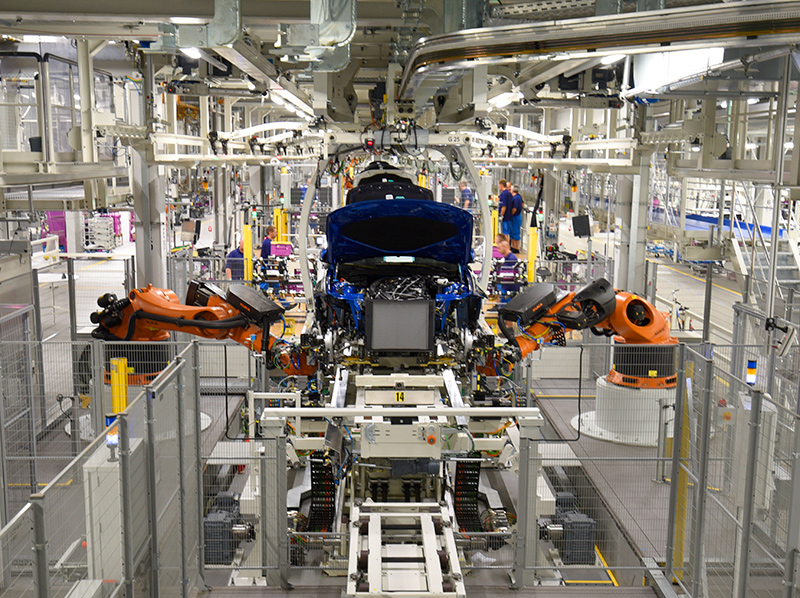

At the BMW Group plant Dingolfing, the marriage line used for putting together the body, drive system and chassis has been replaced by a new, innovative and extremely flexible assembly system.

The new assembly system will have the new higher standards which includes improved quality, process reliability and availability of the system, as well as to factor in ergonomic considerations.

The primary objective was to implement an assembly line with maximum flexibility for equipment installation.

The marriage line had to be able to "marry" BMW 5 series vehicle models fully automatically - regardless of size, weight and product characteristics.

In addition, it had to be possible to integrate future models into the line with minimum effort and expense.

The complete system joins body, drive system and chassis in eight sections and is implemented as a "closed loop".

The process sequence

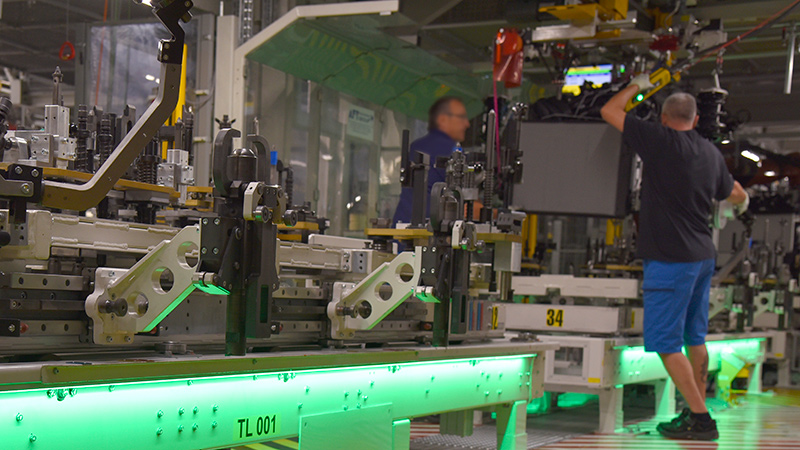

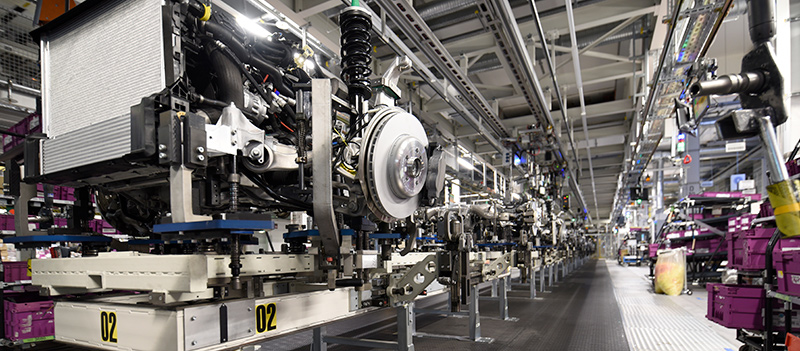

Equipment installation starts with preparing the right model-specific assembly equipment carrier (AEC) from the sequencer, a fully automatic high-bay storage system with 15 AEC spaces.

In response to the commands of a superordinate logistical computer (IPS-L), the empty AECs are taken out of storage and transported to the fitting section by way of a short cross conveyor section.

Here, the AECs are fitted with the equipment and prepared for marriage.

At the first station of the fitting section, the so-called "engaged unit", consisting of the engine, transmission, front axle and radiator, is placed semi-automatically onto the AEC by means of a lifting station.

The engaged unit is infed using an electric monorail system (EMS).

In the robot station which follows, the rear axle is placed on the AEC fully automatically.

The chassis fitting process takes place on a raised conveyor in 7 work cycles to allow for model-specific processing of the drive equipment.

Here, the AEC is fitted with additional components such as the driveshaft, other small parts and bolts, and the components are bolted together manually or semi-automatically.

Next, the AEC is brought to a camera station, which checks to ensure that all the components are installed correctly.

Over 20 cameras take pictures of the individual components, and their position and arrangement is reviewed.

In case of a reject, the equipment unit or the fixtures on the AEC can be corrected manually.

After inspection, the fully equipped AEC is transported to the entrance of the marriage line by way of a cross conveyor section.

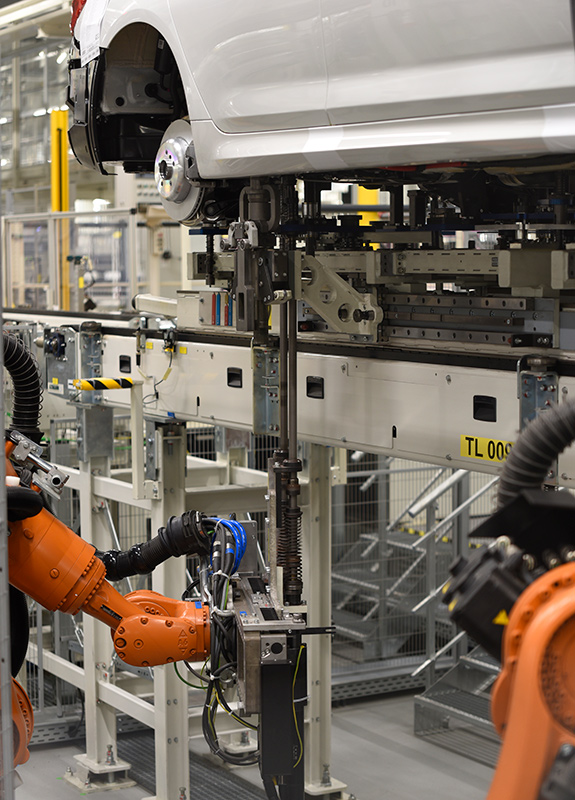

First comes the rough joining operation. Using the "heavy duty EMS", the body is positioned over the work-piece carrier in order to prepare the combined structure for pre-decking.

Then comes the final decking operation, connecting the drive system and body at a single station with 6 robots. Based on the model, a corresponding robot programme is started.

Two robots simultaneously grip the front struts on both sides, and the strut holders on the work-piece carrier are opened.

Monitored by cameras, the robots introduce the struts into the strut bearing.

At the two bolting stations which follow, the drive system is bolted to the body automatically.

The stations each have a back-up station as an emergency strategy. Here, the body and drive system can be bolted together semi-automatically within the cycle time.

At the decoupling station, the bolted body is put back on the heavy duty EMS. Next, the empty AEC is returned to the sequencer and stored until the next cycle.

SAR products and services

As the general contractor, the EBZ Group was responsible for implementing the new equipment installation system.

For this project, SAR was responsible for all the project engineering related to electrical systems with control technology and robotics

SAR's scope of work included the simulations in process, generating the hardware layouts, building the switch cabinet and installing and commissioning the system.

Conclusion

The project team succeeded in implementing the requirements specified by the customer. The result is an extremely flexible assembly system for putting together the body, drive system and chassis.

All the vehicle models with their individual characteristics can be married fully automatically and with a minimum of effort.

And the customer's high standards of quality, process reliability and system availability were also met.

Update Summer 2018:

The marriage line at the Spartanburg plant (USA) has gone into operation and is currently being commissioned at the San Luis Potosí plant (Mexico)

For further information please contact us at

aut@sar.biz