Schmolz+Bickenbach AG is a steel company based in Luzern (Switzerland). We replaced their 30-year old warehouse control system at their site in Bronschhofen (Switzerland).

The old system had served them well for 30 years, but spare parts procurement was becoming increasingly difficult and the system couldn’t keep up.

Quick order processing, optimum routes

If the framework conditions in the supply chain change, the system needs to adapt.

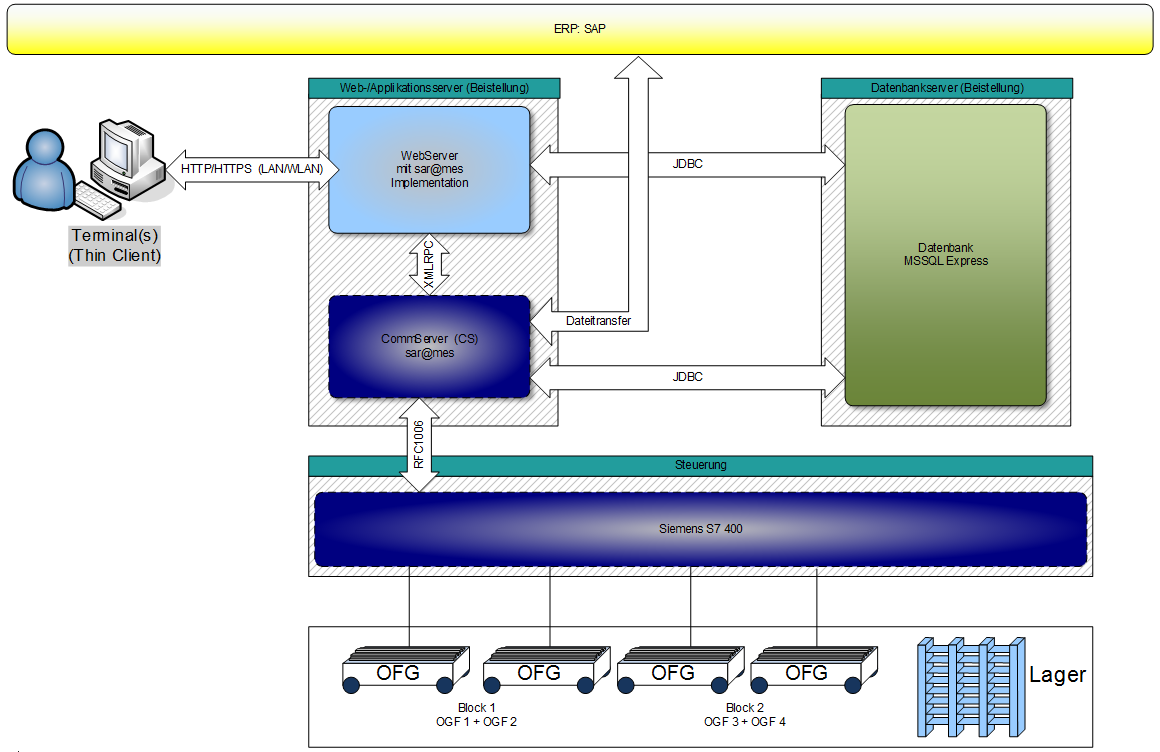

The new system at Schmolz+Bickenbach is based on a modern PLC with sar@mes for planning optimum routes and faster order processing. The existing hardware could continue to be used.

Managed by SAP, moved by sar@mes

The material is managed via SAP and also requested from there. Four upper driving units take containers from a high-bay warehouse and transport them to airlocks.

In the airlocks, the containers are either loaded with new material or material required for further processing is unloaded. The system verifies all actions with a scale and transmits the data to SAP.

The new warehouse management system has been successfully in operation since spring 2019.

Improved work quality and speed

It only took a few days to implement sar@mes. Then production was relaunched and successfully met the daily target. The solution has significantly improved efficiency and user-friendliness.

The software has enabled employees to improve the quality and speed of their work. In the background, SAR ensures seamless communication with the SAP system and ensures a high level of security.

The target of optimising supply routes has been met.

For further information, please feel free to contact us at

its@sar.biz