Otto Fuchs KG is active in the non-ferrous metals industry and produces for a wide range of industries, from the automotive industry to aerospace.

sar@mes for intralogistics

Otto Fuchs manufactures aluminium windows and running rails for the construction industry, for example, using sar@mes as a control system for intralogistics.

SAR software is used from work preparation to dispatch, from process data logging to material flow control.

Cutting, sawing, pressing, heat treatment and packaging are carried out at the work stations.

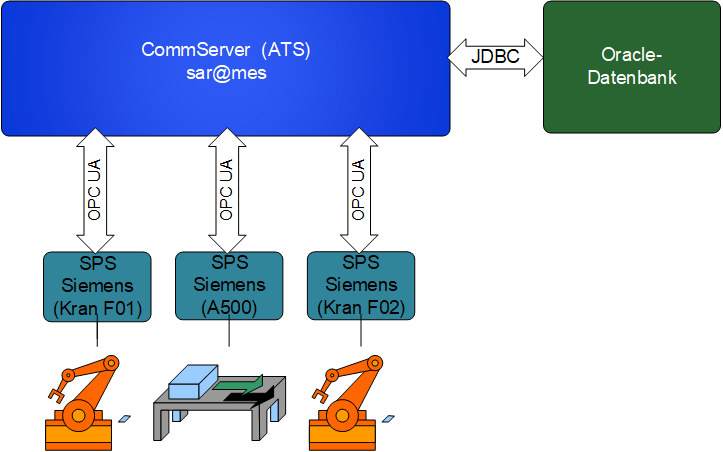

An automatic transport system between the workstations ensures a smooth process including logging.

SAP sets the defaults, sar@mes does the job

The orders from SAP are read in and processed by sar@mes. The system then calculates the transport routes, prioritizes and logs them for traceability of production.

Traceability of production through a web-based interface

For Otto Fuchs it is very important that the traceability of production is guaranteed as before.

The smallest deviations are documented by sar@mes and can be evaluated on any device in the intranet (e.g. supplier, work step, materials used, shift groups).

In addition, the system offers the advantages of a web-based interface such as platform independence and integrated user administration.

For further information please contact us at

its@sar.biz